What is a glue supply system

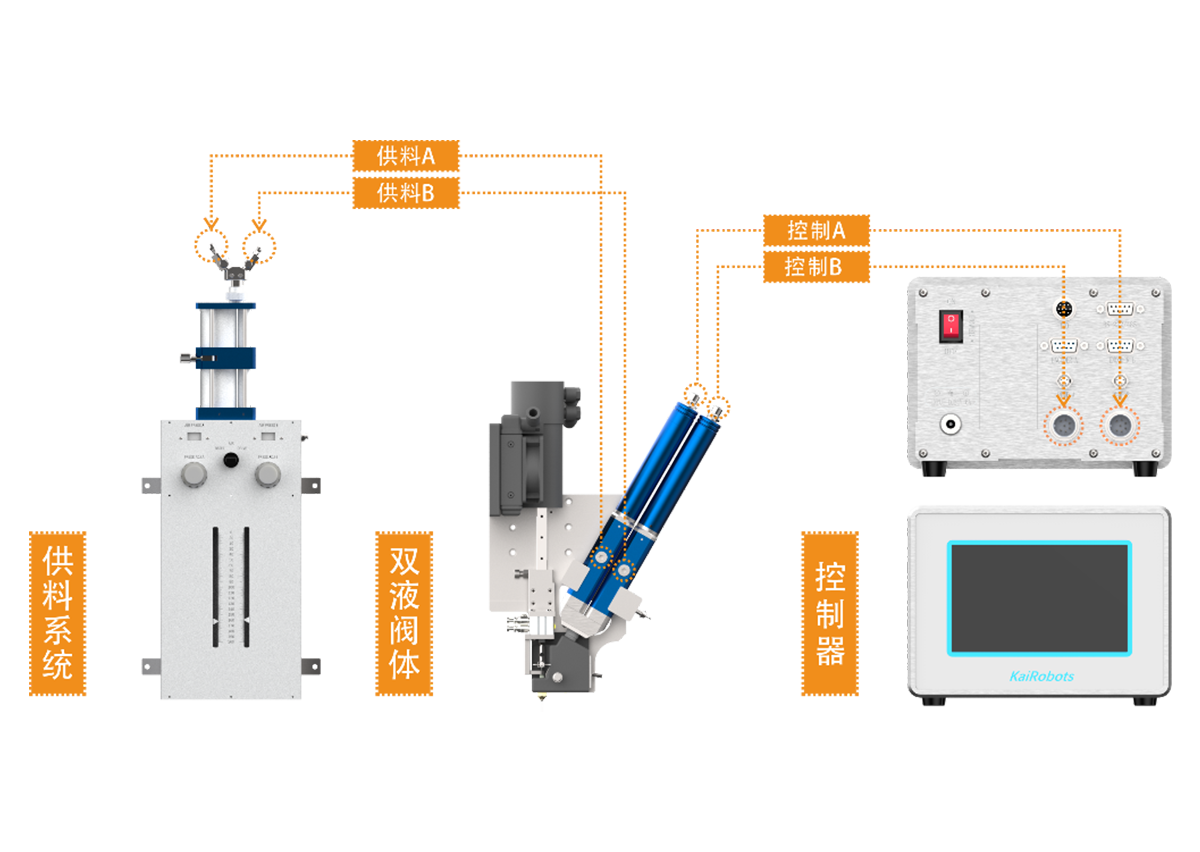

source:m.zscxf.cn | Release time:2024年11月21日1、 Components

Adhesive storage container: This is the storage unit for adhesive. Its size and shape vary depending on the amount of glue used and the production scale. For example, in small-scale handmade production scenarios, the glue storage container may be a simple glue bottle; In large-scale industrial production, the rubber storage container may be a huge metal can with heating or cooling functions. For some easily solidified adhesives, the adhesive storage container may also be equipped with a stirring device to maintain the uniformity of the adhesive.

Conveyor pipeline: used to transport glue from the glue storage container to the location where glue needs to be applied. The material of the conveying pipeline should be selected according to the properties of the adhesive. For example, for highly corrosive adhesives, corrosion-resistant pipeline materials such as special plastics or stainless steel need to be used. The diameter and length of the pipeline also affect the efficiency and pressure of glue transportation, and generally need to be designed according to specific flow requirements and transportation distance.

Pump or pressure device: This is the power source of the glue supply system. If it is a low viscosity adhesive, only a small peristaltic pump may be needed to achieve stable delivery; For high viscosity adhesives, more powerful gear pumps or piston pumps are required. The pressure device can push the glue to flow in the pipeline by applying a certain amount of air pressure or hydraulic pressure, ensuring that the glue can reach the glue application point smoothly.

Flow control and regulation device: It can correctly control the flow of glue. On some automated production lines, by installing flow meters and regulating valves, the flow rate of glue can be adjusted correctly according to the requirements of the production process to ensure the quality and consistency of the glue coating. These devices can be manually adjusted or automatically controlled, such as through a computer control system for real-time adjustment based on preset parameters.

Glue head or nozzle: This is the output component of glue. The shape and structure of the glue head depend on the method and requirements of glue application. For example, when applying glue on a flat surface, a flat glue head may be used; In the dispensing operation, a needle nozzle is required. The glue head can also be equipped with heating or cooling functions to change the viscosity of the glue, making it more suitable for glue application.

2、 Application scenarios

Electronics industry: In the process of circuit board assembly, the glue supply system is used to correctly apply glue (such as chip packaging glue, solder joint protection glue, etc.) onto electronic components. Due to the small size of electronic components, high precision is required for the amount and position of glue. The glue supply system can ensure that the glue is correctly applied to the required position, preventing glue overflow and damage to other components.

Automobile manufacturing: There are many places in automobile production that require the use of glue, such as the adhesion of car interior parts and the application of body sealant. The glue supply system can adapt to different viscosities of glue and different coating areas, ensuring the bonding quality and sealing performance of automotive components. For example, during the installation process of a car windshield, the glue supply system can correctly apply sealant to the edges of the windshield, ensuring the sealing and firmness after installation.

Packaging industry: used for sealing and labeling packaging materials such as paper boxes and cartons. Through the glue supply system, glue can be quickly and evenly applied to the edges of packaging materials or the back of labels, improving packaging efficiency and quality. Moreover, it is possible to flexibly adjust the flow rate and application method of glue according to different packaging materials and glue types, meeting diverse packaging needs.

Furniture manufacturing: In furniture production, the glue supply system is used for splicing wood, bonding panels, and pasting decorative materials. It can ensure the uniform distribution of glue on the surface of wood, improve the bonding strength and aesthetics of furniture. For example, in the production of composite wood flooring, the glue supply system evenly applies glue to the joint surfaces of the wooden boards to ensure that the flooring is tightly and smoothly joined.

prev:

What are the characteristics of a floor standing …

next:

What are the characteristics of vacuum sealing un…

中文

中文 英文

英文

WeChat official account

WeChat official account

Scan your phone once

Scan your phone once

Wechat ID:

Wechat ID:

wechat

wechat

contact

contact

phone

phone